Earthquake Resilient Sustainable Lightweight Steel Buildings

Earthquake Resilient Sustainable Lightweight Steel Buildings

STRUCTURAL STEEL is a very ductile material with

high strength carrying capacity, thus it is very useful to make earthquake

resistant buildings. It is a homogeneous material also. The member sections and

the structural systems can be made very efficient for economical design. As the

steel is recyclable and reused it is a green material. The embodied energy for

the efficiently designed steel structure is less than the RC structure. For

sustainable green building steel is the best material nowadays. Moreover,

pre-engineered and pre-fabricated faster construction methodologies help the development

work to complete within the stipulated time.

In old days wooden buildings were made in highly

earthquake prone areas for its low weight. With the recent advancement of steel

industry if we can make these type of buildings using square hollow sections/rectangular

hollow sections, steel plated/wooden floors and puffed panel walling systems

then it will be more strong and lightweight also. These types of buildings are

green, sustainable and eco-friendly. It is found that wind forces developed in

the structural members are greater than the seismic forces generated in the

same. Because of low mass seismic forces are not generated despite of heavy

ground acceleration. Proper steel bracing systems are provided vertically and

horizontally for stability of the structure. The production of new structural

hollow members, chequered plates, puffed/sandwiched panels have created a new

era in building industry making it more sustainable in all respect.

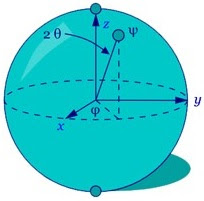

Stability of the steel structures against horizontal forces especially in seismic condition is efficiently possible by Eccentric bracing systems with economic connection details. The EBF is pin – ended, but the beam – column joints are designed for pin ended or for full connectivity. The EBF has several desirable features for seismic resistance. In comparison with CBF system, EBF system can be designed for appropriate stiffness and drift control. The link beam is designed to yield in shear or flexure prior to initiation of yielding or buckling of the bracing member in tension or compression. It is observed that the EBF system is better than MRF system comparing the time period of vibration and base shear participation. The main beams and columns are made of wide flange rolled sections for economical lightweight design.

Dr. Arup Saha Chaudhuri

Professor, Techno Main Salt Lake

Comments

Post a Comment